What’s New in SOLIDWORKS Simulation 2025

By Fortress Institute of Training Solutions Pvt Ltd

https://fortressinstitutetraining.com/solidworks/

Our simulation strategy is straightforward: help you get the best results with minimal effort. SOLIDWORKS Simulation 2025 enables users to simulate more complex scenarios without the burden of explicit modeling, allowing faster simulations without compromising accuracy.

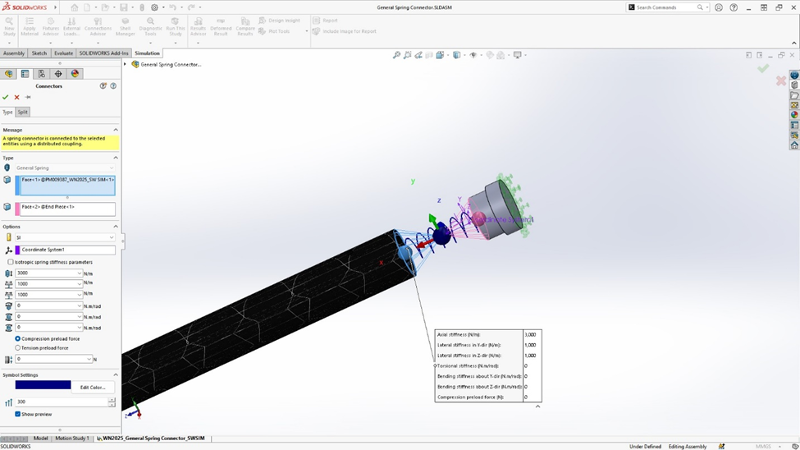

For example, the enhancements in connector and bonding contacts—like the pin, weld connectors, and the new general spring connector—allow you to analyze the relationship between components more effectively. Essentially, every component behaves like a spring; when pushed, it deflects. Because components differ in shape and stiffness, their spring behavior is complex under tension, compression, and torsion.

The new spring connector enables more accurate analysis by allowing you to create a spring with specific properties, such as compressive but not torsional stiffness. This eliminates the need for complex connections between components, letting you focus on the parts you are designing, while using data sheets for components like bushings or bearings.

You can now concentrate on geometry changes early in the design process without the hassle of adding every fastener, bearing, or bolt. Using connectors accelerates simulation without sacrificing accuracy.

https://fortressinstitutetraining.com/solidworks/

Mesh Enhancements

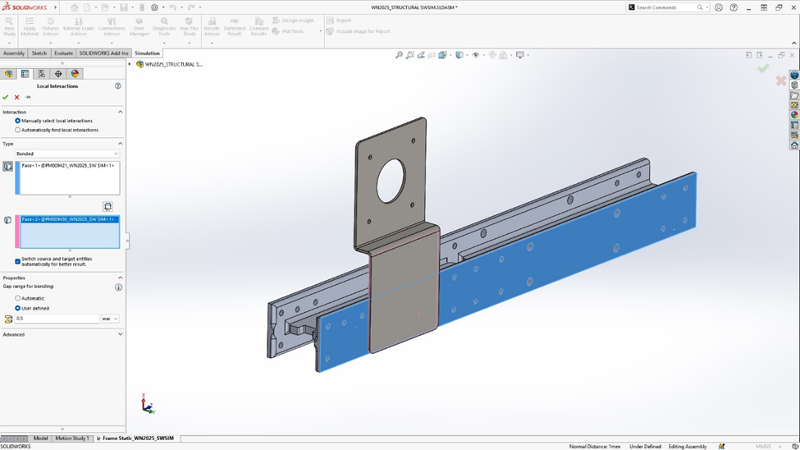

In simulation, the quality of the mesh is crucial. Poor meshing leads to inaccurate results. SOLIDWORKS Simulation 2025 includes several mesh enhancements that improve simulation accuracy and speed. For instance, improved node-to-surface bonded interactions offer greater precision for offset bonding with user-defined gaps. These enhancements benefit various studies, including linear static, frequency, fatigue, and pressure vessel analysis.

For instance, the enhanced node-to-surface bonded interactions improve accuracy for bonding offset defined by a user-defined gap range for bonding. In fact, you can expect improved solution accuracy for all bonding interactions, including solid-solid, shell-shell and solid-shell, that are based on either a draft-quality or high-quality mesh. The studies that support this enhancement include linear static, frequency, buckling, linear dynamics, fatigue, design scenario and pressure vessel.

Accuracy is also enhanced for studies involving bonded curved surfaces where mesh sizes differ. An updated algorithm integrates geometry correction for curved surfaces, reducing stress noise near bonded regions and improving solution accuracy. Assembly work has become more efficient, with mesh adjustments to accommodate components of varying sizes, from fine details to larger areas.

SOLIDWORKS Plastics

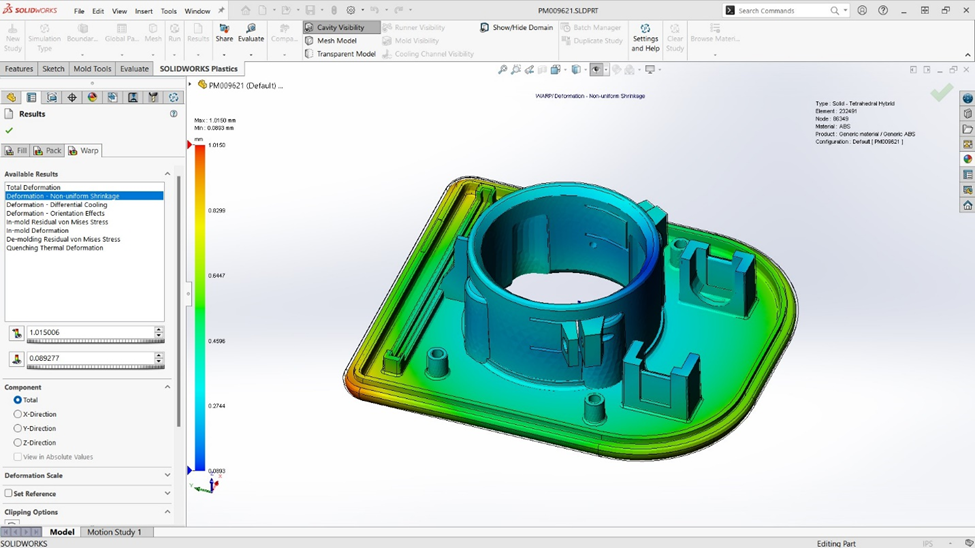

For plastic simulation where you’re looking at the manufacturing process, enhancements help ensure that your part will fit and function the way you intended. For instance, sink mark functionality has been improved so you can accurately predict sink marks when looking at the aesthetics of a part and make geometry adjustments, so you don’t have sink marks turning up where you have walls of different thicknesses coming together.

You can also more easily identify the cause of warpage in the design and injection process to avoid the plastic warping when it comes out of the mold.

SOLIDWORKS Flow Simulation

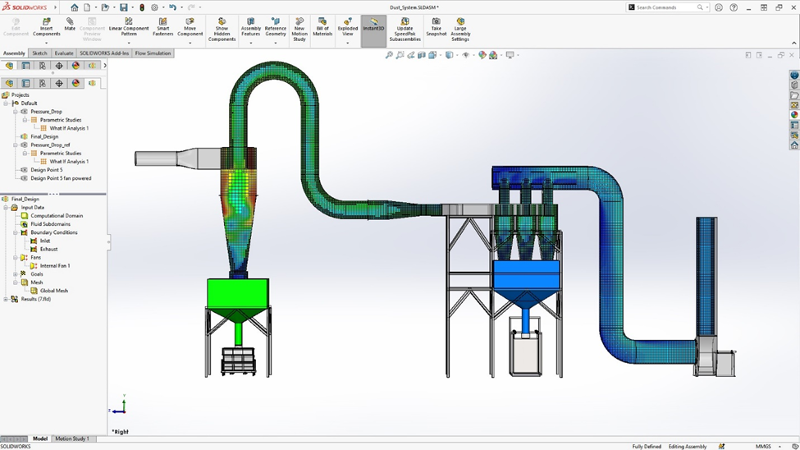

The efficiency of SOLIDWORKS Flow Simulation users has been increased due to two key enhancements: improvements in both mesh performance and selections when working with large models. The impact of both of these enhancements is to reduce the overall simulation process, helping you work smarter and make use of different types of geometry, whether it’s a SOLIDWORKS, SDL, or a mesh file.

The overall theme for 2025 is all about efficiency and providing new tools to help you solve problems faster by allowing you to make good decisions based on your results and get answers fast. https://fortressinstitutetraining.com/solidworks/